- The 2023 Global TB report shows that tuberculosis (TB) cases are showing no signs of slowing down, and the world is behind with goals of the strategy to end TB by 2025.

- While different pieces are moving, like discussions on the need for a new TB vaccine taking place at the Union’s World Conference on Lung Health in Paris this week, and funding being put towards a jab that has shown the most promise in ending TB, a Cape Town-based pharmaceutical company is doing their own work to reach this goal.

- Afrigen Biologics was selected as the World Health Organisation’s mRNA hub in 2021. Since then they have learned many lessons on what it takes to develop vaccines. They shared some of these with us.

How can Africa better prepare for future pandemics? Zano Kunene asks the CEO of local vaccine maker Afrigen. Sign up for answers.

The $5-billion (about R92-billion) needed every year for the next four years for tuberculosis (TB) vaccine research, is the only way to give future generations a shot at ending the disease, experts at the World Conference on Lung Health in Paris said on Thursday.

United Nations member states, including South Africa, pushed for this in their declaration at the United Nations General Assembly in September.

And with the world having recorded the most new TB cases in almost three decades last year, according to the new Global TB report, there’s all the more reason for speeding up the quest for a new jab.

A vaccine that is even just 50% effective — like the promising M72/AS01E candidate — can save 76-million people from getting ill with the disease in 25 years, a 2022 analysis by the World Health Organisation showed. One that is 75% effective can push the number up to 110-million.

At the moment, the bacille Calmette-Guérin vaccine is the only one we have. It sits in the 75% efficacy sweet spot — but the snag is that it has to be given to children who don’t have the TB germ (in South Africa all babies get the jab at birth) and lasts only for about 15 years. This means it doesn’t protect adults and teens — who make up most of the world’s TB cases.

Earlier this year, the Bill & Melinda Gates Foundation and the Wellcome Trust announced that they will jointly give more than R10-billion to get M72/AS01E tested on thousands of people in clinical trials — a move that could get the world a step closer to a new jab.

Having different vaccine options to choose from is important, though, because some may only work on a certain group of the population and so having more than one leaves a bigger number of people protected.

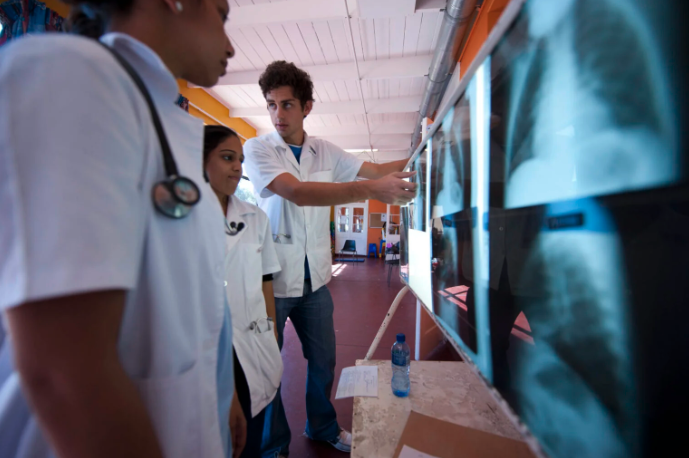

A small pharmaceutical start-up in Cape Town, South Africa is helping.

In October, Petro Terblanche, head of Afrigen Biologics told Bhekisisa at the Grand Challenges Annual Meeting in Dakar, Senegal, that they and a team of South African scientists are working on a new TB shot using mRNA technology. They’re building on what they’ve learnt about making an mRNA vaccine against COVID, similar to the one developed by US-based pharma company Moderna.

But figuring out how to make this type of vaccine from scratch isn’t an easy feat. Terblanche shared five lessons with us that they learnt over the past two years.

[READ] Inside SA’s mRNA hub: What it looks like and how it works

1. Be willing to adapt your plans

mRNA is the genetic code that tells a cell in your body how to make proteins. If used in a vaccine, it can prompt the body to make antibodies against an infection.

Using mRNA to design a new jab against a disease makes the development process — which can usually take up to 15 years — much faster. Moreover, producing such code-based vaccines doesn’t need large labs, which makes the technology a good option to help poorer countries set up facilities for manufacturing shots themselves.

To help with that, Afrigen was chosen to head the WHO’s mRNA vaccine tech transfer hub in mid-2021.

But overcoming intellectual property laws is a nightmare, says Terblanche. That’s because they apply to everything that goes into producing, say, a vaccine or a medicine (like this new anti-HIV shot), not just the final product.

Intellectual property laws govern how companies can market the goods they invent. For example, a patent can give a single company exclusive rights to make and sell a product in a country without competition — for up to 20 years. To make the final product pharma companies either have to sign a voluntary licence, in which the patent holder gives them permission — at a fee — to manufacture the drug based on their method, or be sure to get all the ingredients and equipment from suppliers who aren’t bound by the patent and develop the method themselves.

Afrigen had to overcome this hurdle early on in developing their COVID vaccine candidate. They needed to order a chemical used to make lipid nanoparticles, a fatty substance in which the fragile bits of genetic code are wrapped to help to get them into the body’s cells without breaking down.

But because another vaccine manufacturer holds the patent in South Africa for this essential material used in making this type of jab, Afrigen wasn’t allowed to buy it to make their own product — which derailed their development process, says Terblanche.

So they had to rethink their process and search for an alternative.

This led them to a Chinese supplier of the chemical needed to make the tiny fat droplets and who has freedom to operate because the patent to the COVID vaccine and the materials needed to make it doesn’t apply in China.

The product was just as good as the one they could have bought locally — with an added bonus of being much cheaper.

Says Terblanche: “Be prepared to find alternatives.”

2. Tap into a network of experts

When Afrigen’s scientists started setting up their lab, they had to learn how mRNA technology works real fast. They had lots of experience in working with vaccines — but none in using mRNA to make a jab.

Having a network of experts is crucial when deciding to begin producing vaccines, says Terblanche. “If you’re a start-up company, and you don’t have an ecosystem around you, it’s very difficult.”

In Afrigen’s case, their support system is made up of contacts both within and outside the hub, such as the Medical Research Council, local vaccine manufacturer Biovac and the Medicines Patent Pool. They also work closely with research institutes such as a group at Wits University and biotech companies like Univercells in Belgium.

By drawing on knowledge from different experts in their network, Afrigen was able to learn how to use the tech. Taking part in online webinar workshops every week, scientists at the Cape Town lab were taught how to use the mRNA platform. They also learnt how to successfully get millions of copies of short strings of mRNA by growing bacteria in a special tank, called a bioreactor. (The bacteria contain tiny rings of genetic material for making mRNA and their multiplying in the bioreactor creates something of an mRNA factory.)

As part of a deal with Quantoom Biosciences in Belgium, Afrigen is testing a new way of getting mRNA ready for use in vaccines — at a fraction of what the method used by other manufacturers of these types of jabs cost while maintaining the same quality, says Terblanche.

They also drew on researchers at universities, such as a group from Wits University who has worked with mRNA technology in developing gene therapy for cancer. Both experienced academics and postgraduate students in fields like biochemistry, microbiology, genetics and processing engineering were recruited from some of the local universities to be part of Afrigen’s project.

Says Terblanche: “The fact that we [South Africa] invest in building [scientific] research and development skills at our universities, allowed us to pull people into the [vaccine manufacturing] industry.”

3. Be prepared for the unexpected

When Afrigen was awarded the bid to host the hub in June 2021, the initial plan was for them to get tech transfer from an international drugmaker who was already making mRNA COVID vaccines. This meant they would get all the tools they’d need to rapidly develop the final product, like equipment lists, instructions on how to set up a lab and the methods to make the jabs.

But the Ikea-like flat pack didn’t materialise.

In October 2021, they were told they’d have to go it alone. “We were working under time pressure: we had to build a facility, qualify it [which means the building has to be certified to develop the product], make the vaccine and train people, all at the same time,” explains Terblanche.

This meant they had to use information like patents and research articles that were available publicly and work back to figure out their own way to make the vaccine. Despite many unexpected hiccups, they managed this in three months after opening the doors of their facility in December 2021. By February the next year, they had produced the first batch of a lab-scale vaccine (this is a small amount of the drug that can be tested in the lab to see if it works as planned).

Tests in mice show that the vaccine candidate — which they called AfriVac 2121 — stops the SARS-CoV-2 virus (the germ that causes COVID) from multiplying in lung tissue just as well as current commercial vaccines and was better at prompting the animals’ immune systems to produce antibodies (which fight infections) than the jab it was compared to.

4. Don’t be afraid to do new things

A Pfizer/BioNTech collab resulted in a successful mRNA COVID shot being produced in just nine months — much faster than the conventional cycle of vaccine development. Producing a shelf-ready product so quickly came off the back of about 15 years’ experience in working with mRNA technology for making cancer drugs.

Although it took Afrigen three months to develop a vaccine candidate that was worth taking further because of promising early lab results, the team were navigating uncharted territory in getting to a jab that would be ready for clinical trials in humans.

South Africa has never had facilities that produced vaccines from development to manufacturing, so getting a licence for this from the country’s medicines regulator, Sahpra, was an unknown, says Terblanche.

The Medicines and Related Substances Act says that to produce vaccines for humans a manufacturer needs to have a Good Manufacturing Practice (GMP) certificate. Having these credentials means that the facility and all the processes used in making the product are of high enough quality to be sure it’s safe for human use.

To scale up from being a lab — which can only produce proof-of-concept vaccines — to a GMP-certified facility that can make commercially shelf-ready jabs, there are over “700 standard operating procedures, the use of 402 pieces of equipment and 270 quality control assays [checks to make sure a substance if of high quality]” that need to be developed and vetted to get the sign on the wall, says Terblanche.

Afrigen has already started upgrading their laboratory by ordering specified pieces of equipment and installing utilities like steam gas lines, which they aim to have completed by July next year, to allow them to produce a vaccine that can be used for clinical trials in humans.

Says Terblanche: “We didn’t get the methods; we had to develop and validate them ourselves. So I said to my team: ‘Start reading and learning.’ Realising that you have to expose your team [to new things] is definitely one of the lessons we learnt.”

5. Know how to manage your money

Funding is an integral cog in the machine that is vaccine manufacturing.

In the early stages of the COVID pandemic, vaccines could be developed rapidly because there was no shortage of funding for their development.

“It’s difficult to innovate and perform without funding,” says Terblanche. And, she adds, once you’ve secured the money, things can change unexpectedly, which impacts a project’s budget. So managing finances and having security are important parts of successfully developing a vaccine.

The hub’s initial budget from funders, including the African Union, the South African government as well as those of France and Canada, was based on their receiving full tech transfer. The money was to go towards scaling up their labs, training partners in other low-income countries and then rapidly developing the jabs.

But things changed when they didn’t get the promised package and they needed to pivot to developing the technology from scratch while sticking to the original budget. On top of that, they had to find new suppliers for raw materials or be prepared to pay more — both options that could have depleted the initial kitty of funds. For example, if Afrigen were not able to find a different supplier for the raw material needed for the lipid nanoparticle, they may have needed to pay more than planned.

You also need to budget for upscaling your team, says Terblanche. Afrigen’s team grew more than 10-fold — from 12 people to 134 — in 18 months.

Concludes Terblanche: “We learned how to deliver a huge scope of work under time pressure within tight budgets.”

Zano Kunene is a health journalist at Bhekisisa.